SERVICES

LTI

YOU BET!

We Can Handle It.

HOW WE SHAPE AND PROTECT

YOUR BRAND

- With the most consistent reproduction and color available for both UV and water-based inks

- With QRM (quick response manufacturing) that delivers reduced lead times

- By staffing a highly trained and experienced team of professionals

- By listening closely to our customers’ needs

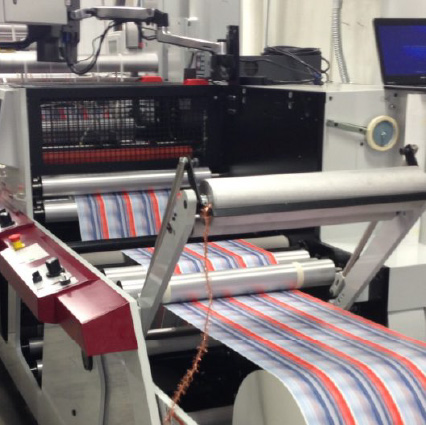

- With non-stop automated machinery — maximizing efficiency & lower cost

- With graphic reproduction accuracy and color matching using Servo

INDUSTRIES WE SERVE

LTI Serves Most Industries

- Consumer Products

- Food & Beverage

- Health & Beauty

- Lottery

- Nutraceuticals

- Promotional/Direct Mailing

- Apparel

- and more...

OUR WIDE RANGE OF CAPABILITIES

- Two 20" Wide Press

- Aluminum Foil Lids

- Aluminum Labels/Printing

- Bar Code Labels

- Clear No-look Labels

- Combination Printed Labels

- Coupon and Coupon Labels

- Custom Folding Cartons up to 18pt.

- Digital Sheet-Fed Printing

- Embossed Tags & Labels

- FleyeVision: 100% print inspection System

- Halo-graphic Labels

- Heat Seal Pouches

- Hot Foil Labels

- Laminate In-Line

- Magnetic Tags & Labels

- Metallic Labels

- Opaque Labels

- Outdoor Labels

- Peel & Reseal Labels

- Pressure-Sensitive Labels

- PVC Backer Cards

- Re-laminate / De-laminate Labels

- Scratch Off Labels

- Scratch-n-Sniff Labels

- Security / Anti-Counterfeit Labels

- Shrink Sleeves (printed and clear)

- Static Cling

- Tamper-Evident Labels

- Through the Container Labels

- Translucent & Transparent Labels

- Tub, Lid, & Canister Labels (PE & PP)

- Vinyl Tags & Labels

- Wafer Seals

SOLVENTLESS LAMINATION SOLUTION

Solventless Lamination: Material, Time and Cost Savings

LTI uses a film lamination process that combines solventless adhesives to enable the slitting of food-grade flexible packaging within hours of lamination. This is FDA regulation compliant and provides our customers with material, time and cost savings!

ANILOX CLEANING SERVICE

LTI's Anilox Cleaning Service includes:

- Full inspection of the roll checking for any dings, scratches, or damaged cells

- The journals, bearings, and drive gear are inspected

- The roll is cleaned with Real Cleen and left to soak for 20 min

- The roll is then placed in the Caresonic tank for the deep cycle treatment

- This process is repeated until all the cell openings are clean and free of any built-up ink or grit. It is followed by an inspection with a cellspec microscope so we know the true BCM of the roll.

- Your anilox roller will now perform to its fullest ability.

LTI makes it easy: Just ship us the rolls, we perform the procedure and ship them back!

LTI

Shaping Brands

LET'S DISCUSS YOUR NEXT PROJECT

"*" indicates required fields